Plants often undergo repair work and modifications in line with plant maintenance and upgrades. When undertaking the design work for such repairs or modifications, SKS implements onsite surveys to analyze current plant conditions and take the necessary measurements, etc. The accuracy of onsite surveys can affect design and construction schedules and as a result, 3D laser scanners are used to take highly precise measurements of even the most minor details which are then applied to the design process.

SERVICE

01

Scanning

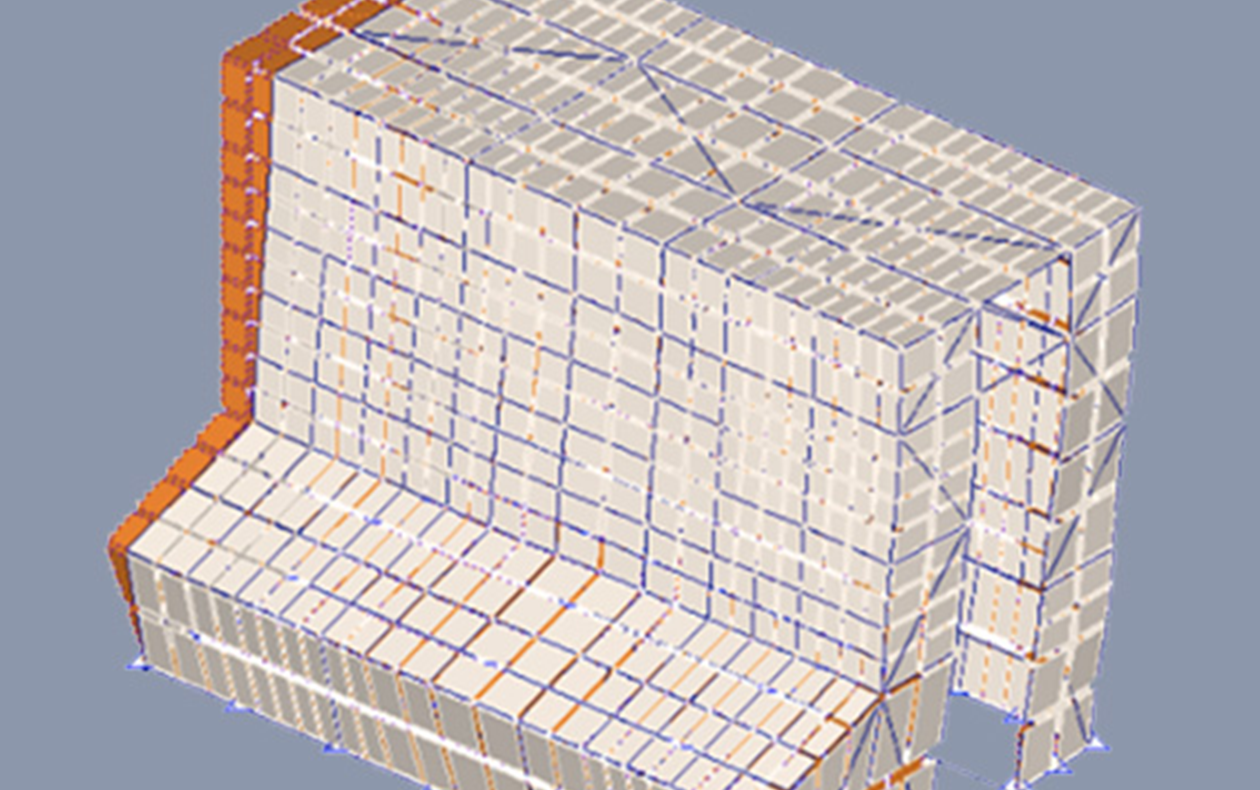

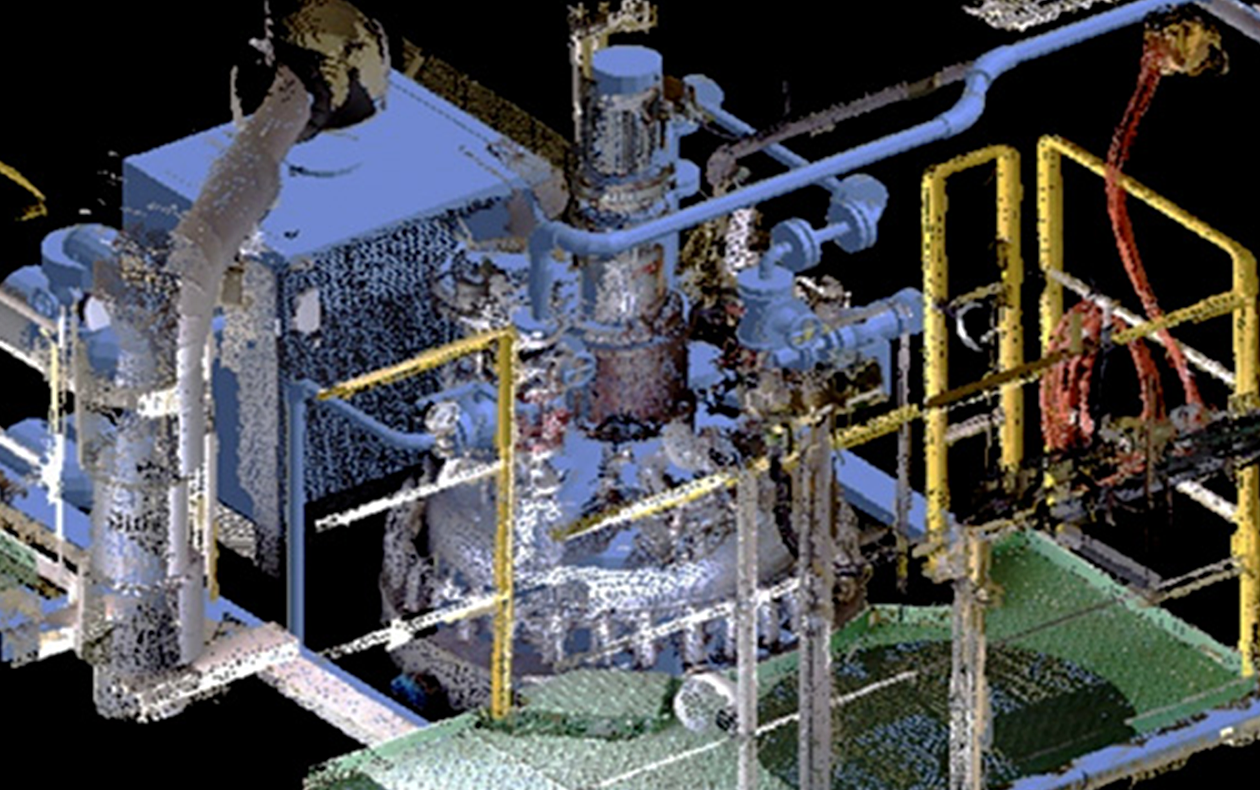

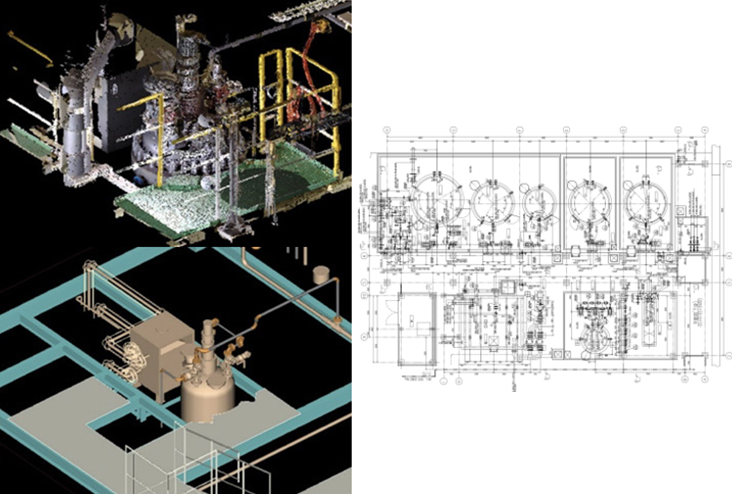

Improving the accuracy of existing plant surveys for the purpose of repair work and modifications has a significant impact on the quality of the following design and construction processes therefore measurements are taken to millimeter accuracy using a FARO Focus 3D laser scanner. One scan enables measurements over a broad area, with a vertical range of 300° and horizontal range of 360° and by combining the point cloud data, it is possible to reproduce the existing plant on a computer with a high degree of visual accuracy.

SERVICE

02

Use of measured data

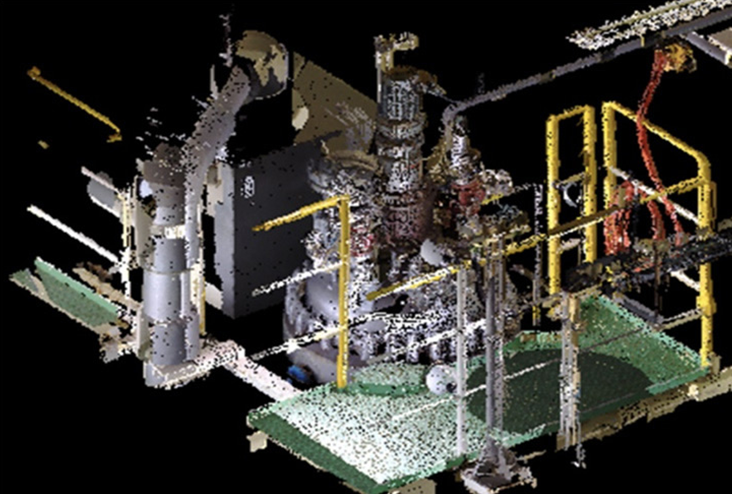

The captured point cloud data is then used for modeling of the facilities following modification using point cloud processing software, such as Galaxy-Eye and Infipoints, etc. and 3D CAD and this can be used to carefully review plans with the client, for interference checks with existing equipment, planning how to move equipment into the plant and removing old equipment all on a computer. Further, data for the piping and piping support structures generated from this modeling process can then be transferred to analytical software, such as AutoPIPE or STAAD pro to realize an integrated design.

SERVICE

03

Integrated design using 3D CAD

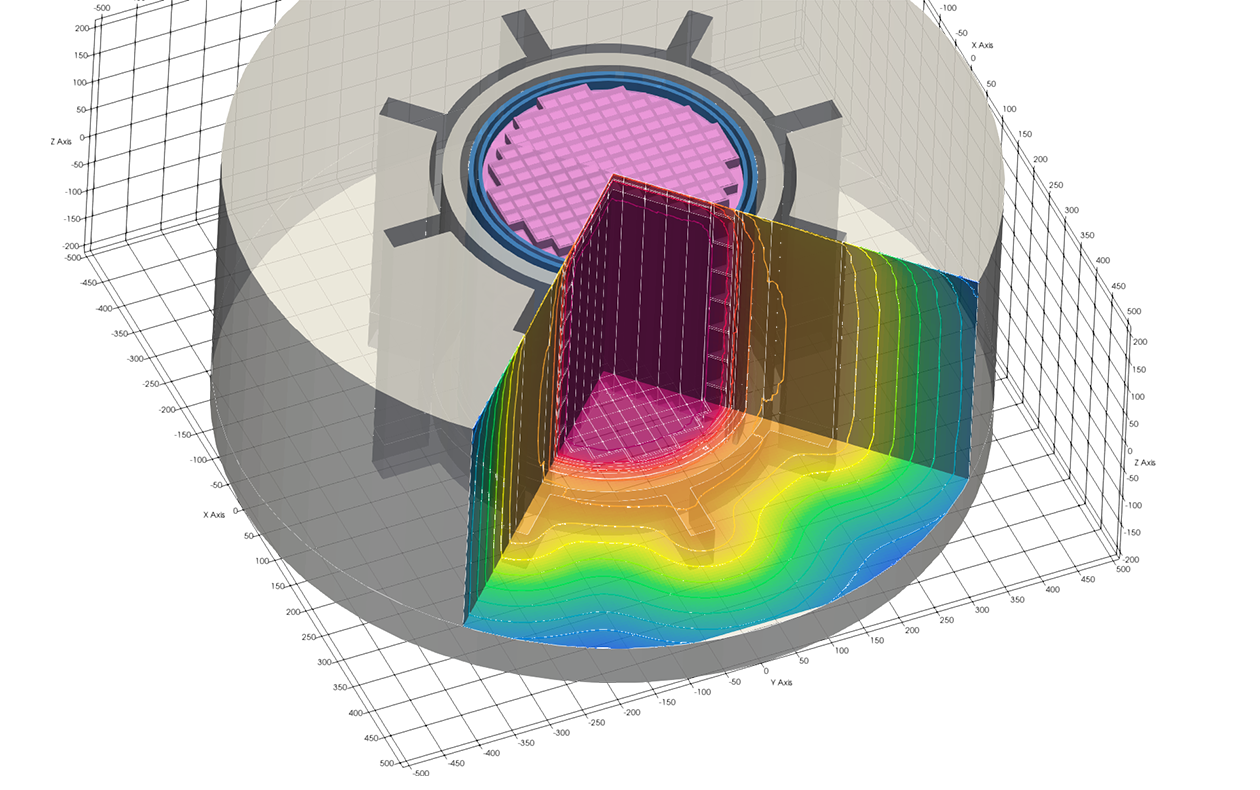

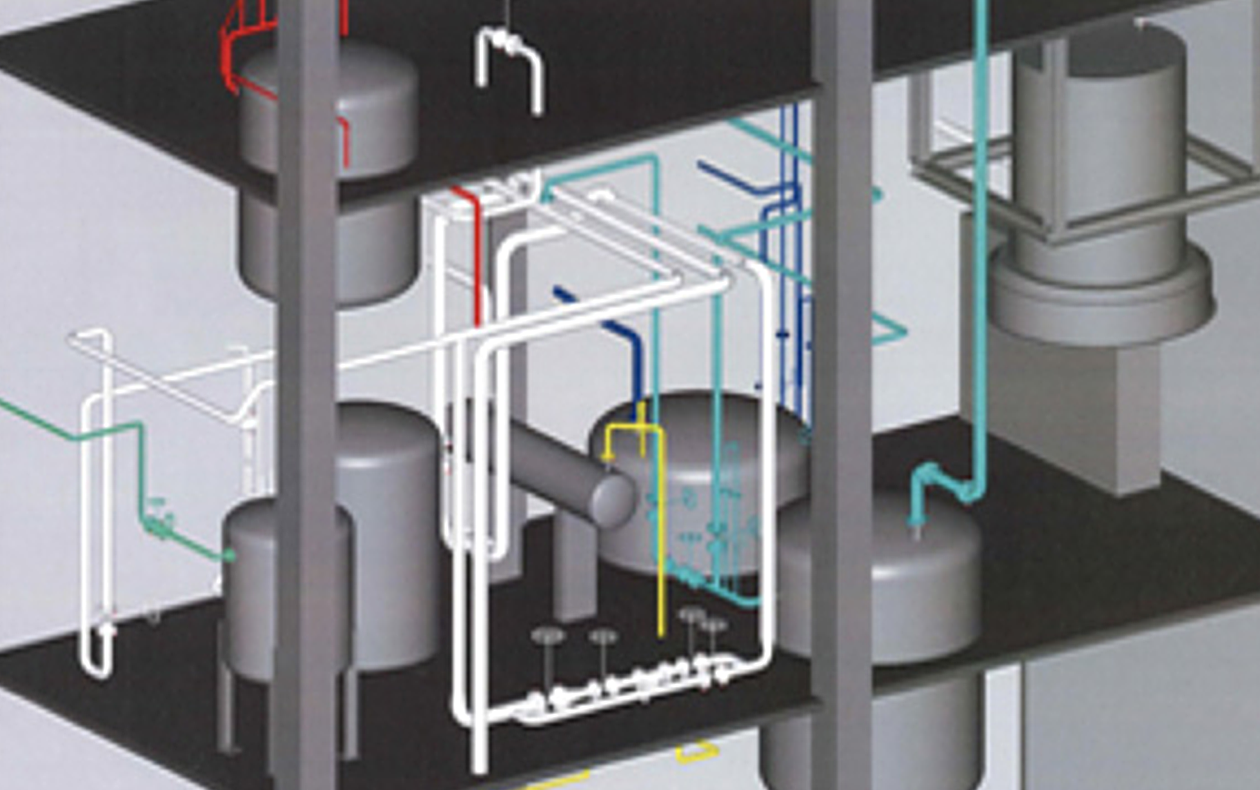

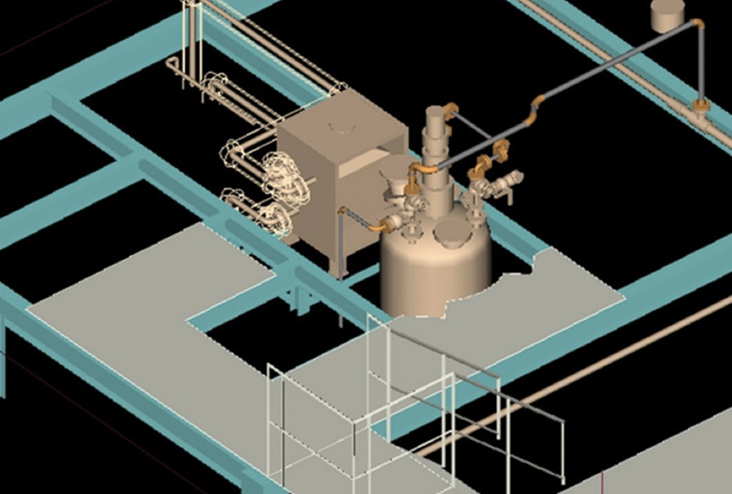

Captured point cloud data is used in the design of the new facilities using 3D software, such as EYECAD or PLANT 3D to achieve an integrated design approach, including piping system design, piping system plans to total materials. Further, by conducting design reviews using models created using 3D CAD, it becomes possible to incorporate the ideas of the customer using the plant and manufacturers responsible for the work in the early stages, reducing the need for any corrections once the work is complete.

SERVICE

04

Plant as-built modeling

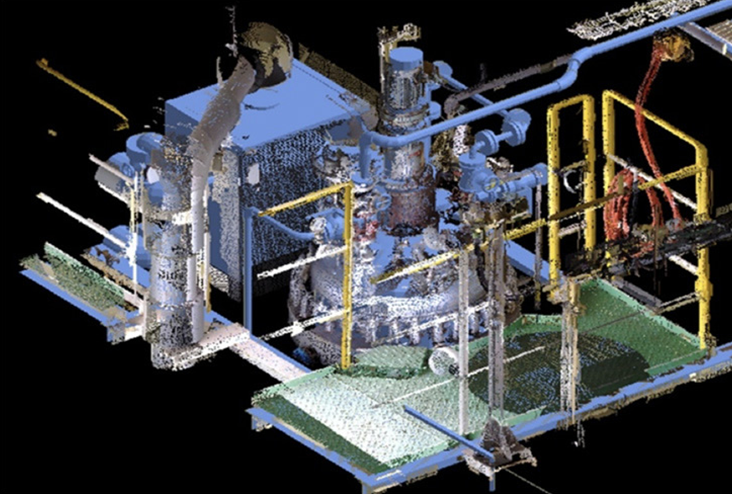

There are often no plans from the time they were built or when modifications were carried out for plants that have been in operation for a long period of time. In such cases, by taking a 3D scan of the plant and saving the point cloud data, it can be used to assist in modifications in the future. The necessary data can be extracted from scanned point cloud data and used in the design process. Further, modifications are scanned after the work is complete and by maintaining the latest point cloud data, the data can then be used to plan future work projects in high visual accuracy on a computer.

SERVICE

05

Utilizing VR/MR

Cutting edge VR(virtual reality) and MR(mixed reality) technology is used in the plant design. VR enables one to visualize structures in the design stage at full scale, and increases operational efficiency by allowing one to perform interference checks and maintenance considerations with piping and other machines, while with MR is useful in coordinating design and onsite considerations, e.g. by projecting equipment and piping in the design stage onto the existing environment, and aiding the design of onsite ideas and additional structures. We aim to realize your anticipated future designs by providing novel design services using cutting-edge technology.